.jpg)

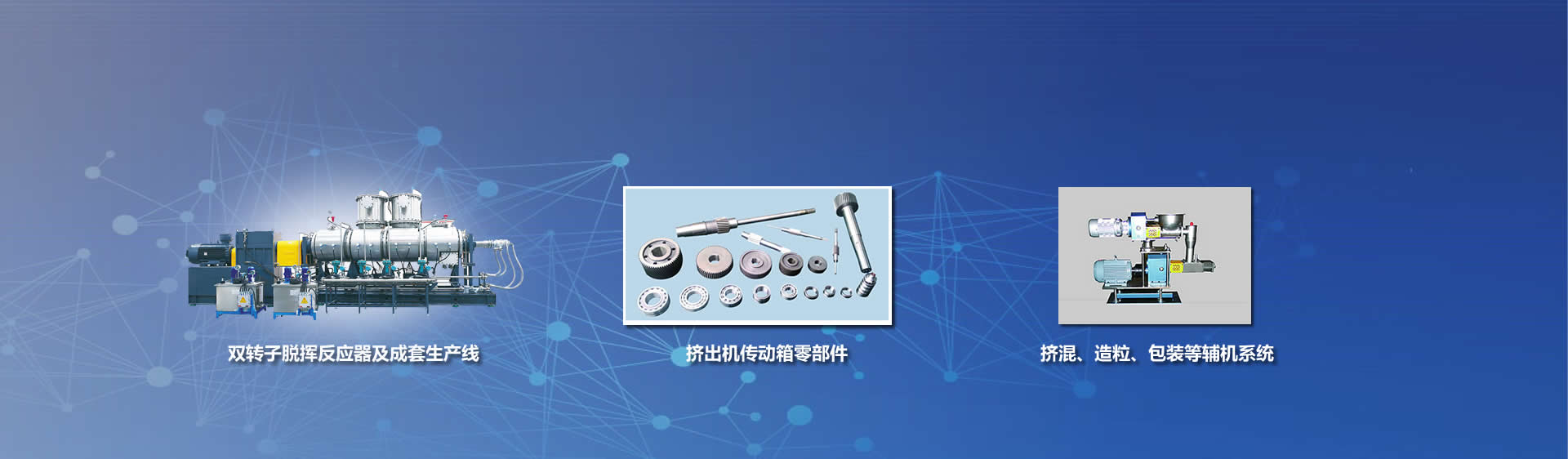

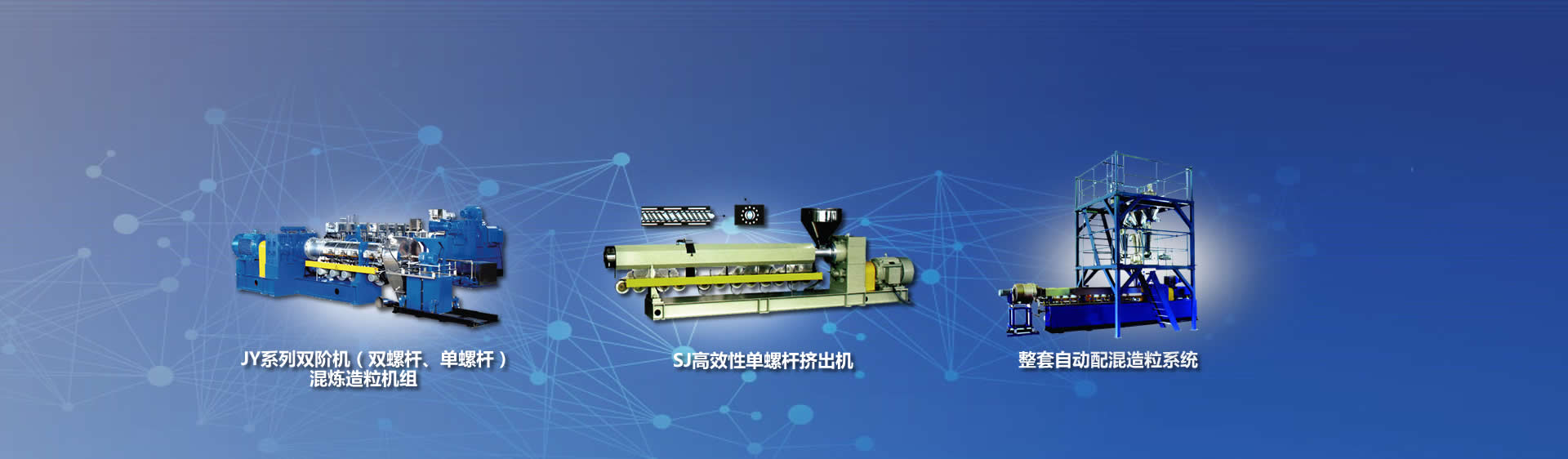

应用领域Application field

管链输送机是一种输送粉状、小颗粒状及小块状等散状物料的连续输送设备,可以水平、倾斜和垂直组合输送。广泛应用于精细化工、塑料工艺、农药矿石、建筑材料、食品工业等。

The pipe chain conveyor is a continuous conveying device for conveying bulk materials such as powder, small particles and small blocks, which can be transported horizontally, obliquely and vertically. Widely used in fine chemicals, plastics, pesticides, ores, building materials, food industry, etc.

特点Characteristics

●容积式输送装置 , 可实现物料的输送和计量 。易于实现集中控制,提高自动化程度,满足现代企业对环境保护的要求

●结构紧凑 , 占用空间小, 可以三维改变输送方向 。

●被输送的物料从进口到出口法兰之间是处于密闭状态的。出口不必设置除尘器。 在输送物料时可充装气体。运输中能保证没有粉尘泄漏到环境中。

●物料沿着管子平滑输送,基本上没有内部运动, 所以物料破损少,缓慢的弯道输送使很少的物料颗粒产生碎屑。

●根据不同的加料情况,进口之间可相距超过10米远。

●链轮有优化的肩,设计优化,使用硬化链条具有最小磨损。

●特殊的输送盘 ,具有极低的磨擦系数和稳定的输送能力。

● Volumetric conveying device for material conveying and metering. Easy to achieve centralized control, improve automation, meet the requirements of modern enterprises for environmental protection

● Compact structure, small footprint, can change the conveying direction in three dimensions.

● The material being conveyed is in a closed state from the inlet to the outlet flange. It is not necessary to install a dust collector at the exit. The gas can be filled while conveying the material. No dust can be leaked into the environment during transportation.

● The material is smoothly conveyed along the pipe, and there is basically no internal movement, so the material is less damaged, and the slow curve conveys so that few material particles generate debris.

●Depending on the feeding situation, the inlets can be more than 10 meters apart.

●The sprocket has an optimized shoulder, optimized for design, and uses a hardened chain for minimal wear.

●Special conveying tray with extremely low friction coefficient and stable conveying capacity.